Lithography Printing vs Digital Printing

Read time: 6 minutes | Author: PRI Graphics | Posted: January 4th, 2023

Lithography Printing vs Digital Printing

We asked our Phoenix print professionals here at PRI Graphics & Signs to discuss lithography vs digital printing.

Over the past few decades, digital printing has emerged as a popular alternative to lithography. Even though there has been a significant shift in recent years toward digital printing, there are some things that sheet-fed lithography can do that digital can’t and may never be able to do (or do as effectively).

So, let’s explore lithography vs digital printing.

What is Lithography?

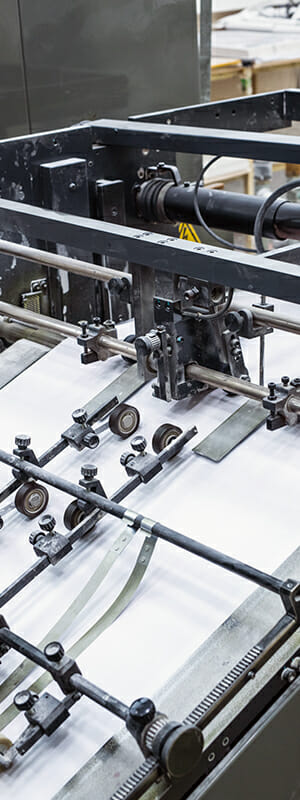

Sheet-fed lithography is a printing process that has been used for centuries to produce high-quality prints on a variety of materials, including paper, cardboard, and metal.

It is a sheet-fed printing process that involves printing on sheets of paper rather than continuous rolls. This creates a print plate or film that contains images or text. The images or text are then transferred onto a printing surface (paper or fabric) using a variety of techniques, such as offset printing or screen printing.

Lithography is a widely used printing method, particularly for large-quantity production of:

- Books

- Magazines

- And other long-run printed materials requiring high-quality printing on a variety of paper sizes

What is Digital Printing?

Digital printing involves creating an image or text using a computer and printing it directly onto a printing surface. Doing so, rids the need for a physical print plate or film.

This has led to a significant increase in the popularity of digital printing, particularly for small format printing in the printing industry.

There are several factors that have contributed to the rise of digital printing and the apparent decline of lithography. Yet, as we stated earlier, digital can’t do everything that lithography can.

Benefits of Digital Printing

Digital Is Accessible & Affordable

One of the main drivers of this shift from lithography to digital printing is the increasing availability and affordability of digital printing technology.

Flatbed digital printing is generally more cost-effective than lithography, especially for smaller print runs. This is because there is no need to create a physical print plate or film, which can be a time-consuming and expensive process.

Digital printing equipment has also become more advanced, affordable, and widely available. Making it more accessible to small businesses and individuals.

Digital is Fast & Convenient

Another factor is the speed and convenience of digital printing. It allows for faster turnaround times, as there is no need to wait for the print plate or film to be created.

Printing digital files allow for faster turnaround times and the ability to make any necessary changes to a document or design quickly and easily.

Digital Is Flexible & Allows for Smaller Print Runs

Another advantage of digital printing is its flexibility.

Digital printing allows for a greater range of customization options. As it is easier to make changes to an image or text on a computer than it is to create a new print plate or film.

This makes digital printing particularly useful for businesses that need to produce a variety of materials, such as marketing materials or promotional flyers, on a regular basis.

Smaller print runs can also be more cost-effective for small to medium-sized businesses even for large-format printing.

Digital Is More Environmentally Friendly

In terms of lithography vs digital, digital printing has a smaller environmental impact than lithography.

Traditional printing processes, such as lithography, require the use of printing plates and chemicals, which can be harmful to the environment.

Digital printing eliminates the need for these materials and can be powered by renewable energy sources, making it a more sustainable option.

Benefits of Lithography vs Digital Printing

While digital printing has many benefits, it is not necessarily replacing lithography entirely. Despite the many advantages of digital printing, lithography is still widely used and has its own set of benefits.

In some cases, lithography may still be the more appropriate choice, particularly for larger print runs or for printing on certain materials.

Additionally, lithography is still capable of producing very high-quality prints, and for some businesses, this may be a priority.

Lithography Can Print on a Wider Range of Materials

Sheet-fed lithography is capable of printing on a wider range of materials than digital printing, including thicker papers, metals, and other non-paper substrates.

It can be used to print on paper, cardboard, and even metal and other non-paper materials. This flexibility can be particularly useful for businesses that need to print on a variety of materials, as it allows them to use the same printing process regardless of the material they are working with.

Lithography Can Print Larger Print Runs

Sheet-fed lithography is better suited for larger print runs, as it is more efficient and cost-effective for printing in quantities of 1,000 or more. Digital printing, on the other hand, is generally more cost-effective for smaller print runs.

Lithography Is Better & More Cost-Effective for Volume Printing

Lithography is often preferred for printing high volumes of materials such as larger runs of books and magazines. Printing large runs is also much more cost-effective with lithography. This makes it a good option for businesses that regularly produce large quantities of printed materials.

Lithography Offers More Vibrant Colors & Higher Resolution

In some cases, sheet-fed lithography can produce prints of a higher quality than digital printing. This is because it is capable of printing with finer detail and more precise color matching. With lithography, you have a much higher resolution, and the color prints are more vibrant.

Sheet-fed lithography can also print a wider range of colors than digital printing, as it uses a different color printing process.

Lithography is capable of producing very fine and precise details, as well as smooth gradations of color. This makes it an excellent choice for printing materials that require a high level of detail or visual impact, such as brochures, magazines, and high-end marketing materials.

Summary

So, is digital printing taking over lithography?

It’s certainly true that digital printing has gained in popularity in recent years and has become an increasingly viable option for many businesses that regularly print smaller runs.

Overall, it’s clear that digital printing is an increasingly popular option for businesses of all sizes. However, it’s important to carefully consider the specific needs and goals of your business when deciding between lithography vs digital printing.

Both methods have their own strengths and can be used effectively in different situations.

There may come a time when digital printing is able to match or exceed the capabilities of sheet-fed lithography in certain areas. However, currently, sheet-fed lithography remains a valuable and important printing method for many businesses.

Connect with PRI Graphics & Signs in Phoenix

The decision to use lithography or digital printing should be based on a variety of factors, including the volume of materials to be printed, the desired print quality, and the sustainability of the printing process.

If you still have questions about lithography vs digital printing, please contact our printing professionals here at PRI Graphics & Signs in Phoenix AZ.

No printing project is too large or too small and we service clients throughout Arizona and across the continental United States.

We can be reached locally, in Phoenix at 602-393-3131 or call us toll-free at 1-877-409-8889

You can also reach us by email.